Technologies

04 Cutting

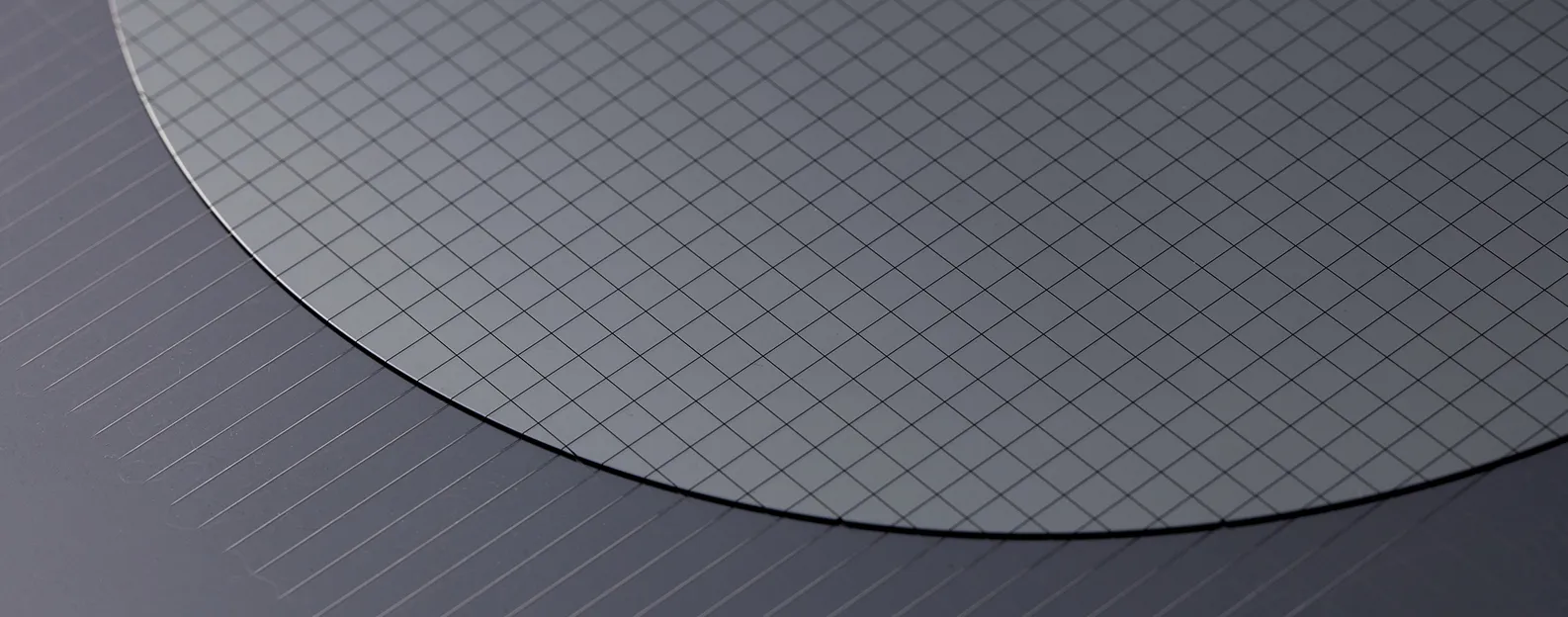

Cutting

Cuts metals, plastics or even SiC A versatile high-speed cutting technology

SoundCutting utilizes the power of sound for damage-free cuts in either atmosphere or liquid. This versatile cutting technology covers a wide range of metals, plastics, and even difficult-to-cut materials like SiC.

For semiconductor manufacturing, it used to be common practice to cut silicon wafers using self-sharpening diamond blades. These keep their sharpness by wearing down and breaking off used diamonds. The downside of this process is that with ever-growing facilities, the number of blades consumed adds up to a significant amount of production cost.

Offering solutions for large production volumes and increasing efficiency with innovative technologies is part of the Ultex manufacturing ideology. SoundCutting is our answer for cutting soft, hard, and tough materials with just the power of sound.

SoundCutting features

- Virtually zero wear on blade

- No blade dressing needed

- No built up edges or clogging

- Minimal chipping

- High cutting speeds

- No damage to workpiece

- Uses only water, no special cutting fluid needed

Cutting videos

-

High speed cutting SiC at 20mm/s

-

PowerBlade®