Technologies

Metal bonding, soldering, and cutting with only the power of sound.

「SoundPower」 has been the focus of our research and development ever since Ultex was first established. SoundPower systems need only power, air, and water – an exceedingly simple solution. Our systems allow for metal bonding and cutting with exceptional precision, all while reducing waste products and environmental impact. We are also constantly developing new applications for work with parts of various geometries, surface treatments, or even non-metals. Research in our laboratory continues every day to offer the best solutions to our customers’ needs.

Mass production with

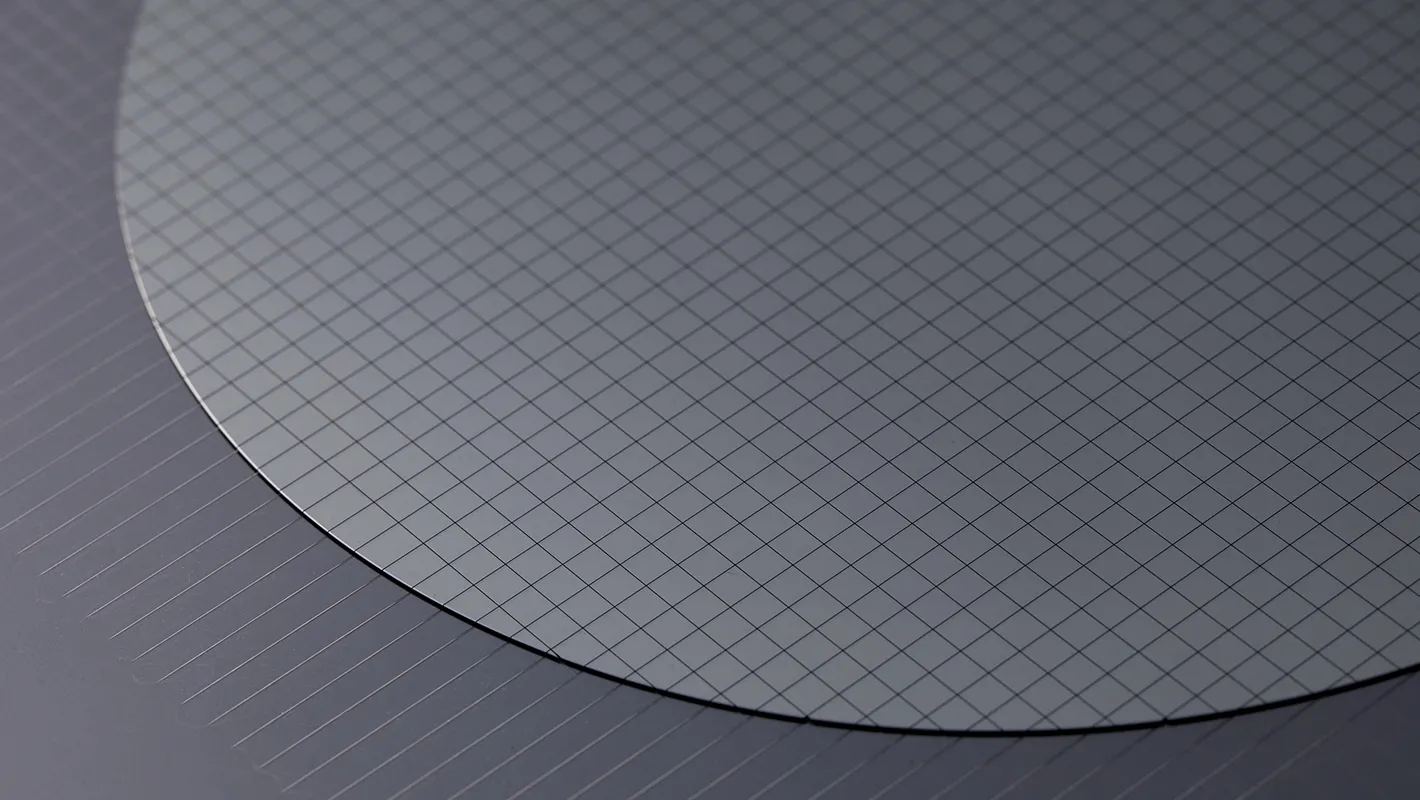

zero trouble

Ultex SoundPower technology is used in the production of hybrid vehicle Ni-MH and Li-ion batteries, power modules, and various electronics. Our streamlined processes consistently achieve exceptionally low defect rates.

-

01

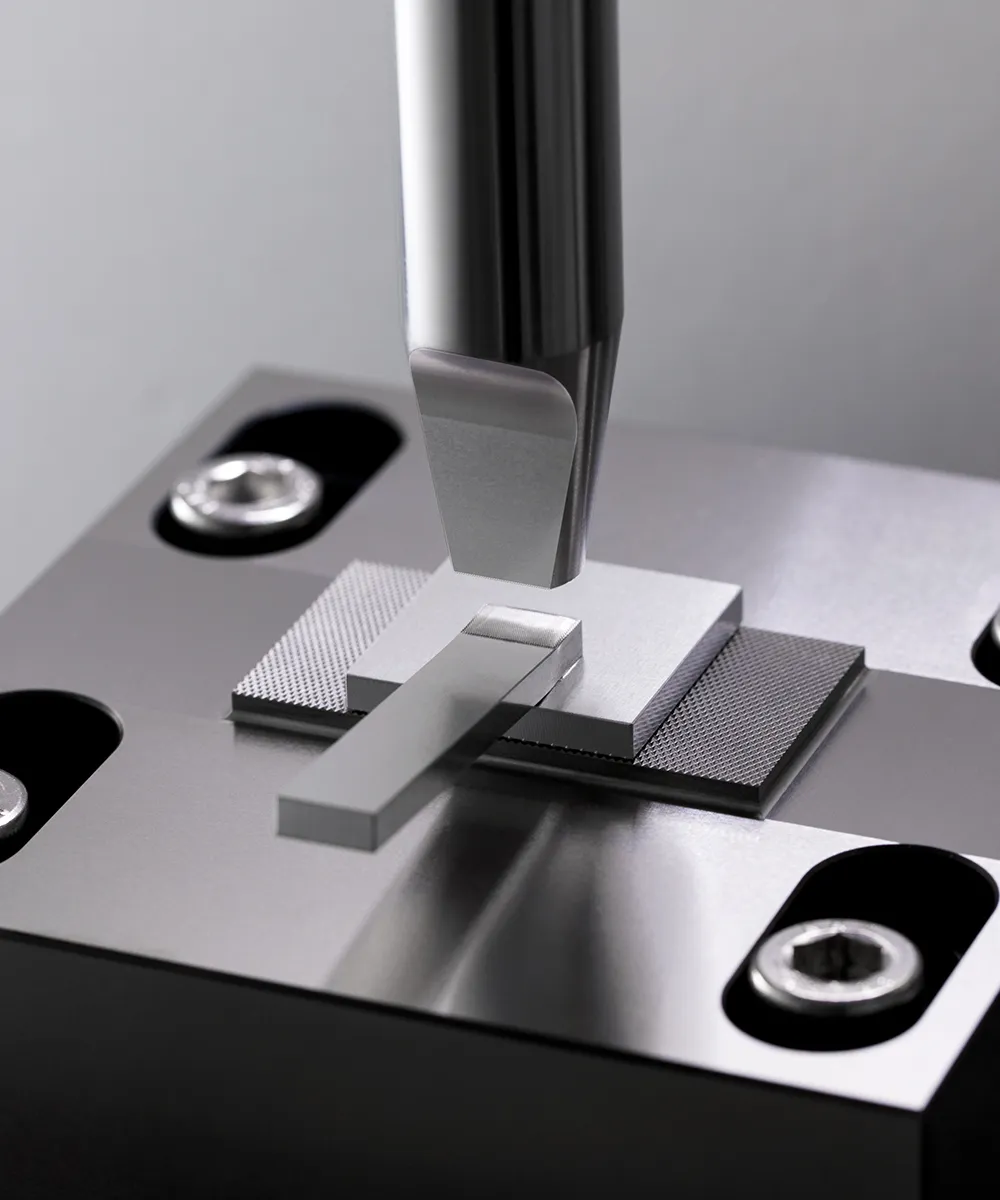

01Bonding

SoundBonding utilizes the power of sound to create interatomic bonds between parts while in the atmosphere and at room temperature. It allows for bonding between dissimilar metals, like copper and steel, or even nonmetallic materials like ceramics. SoundBonding has also solved core problems for lithium-ion battery mass production.

-

02

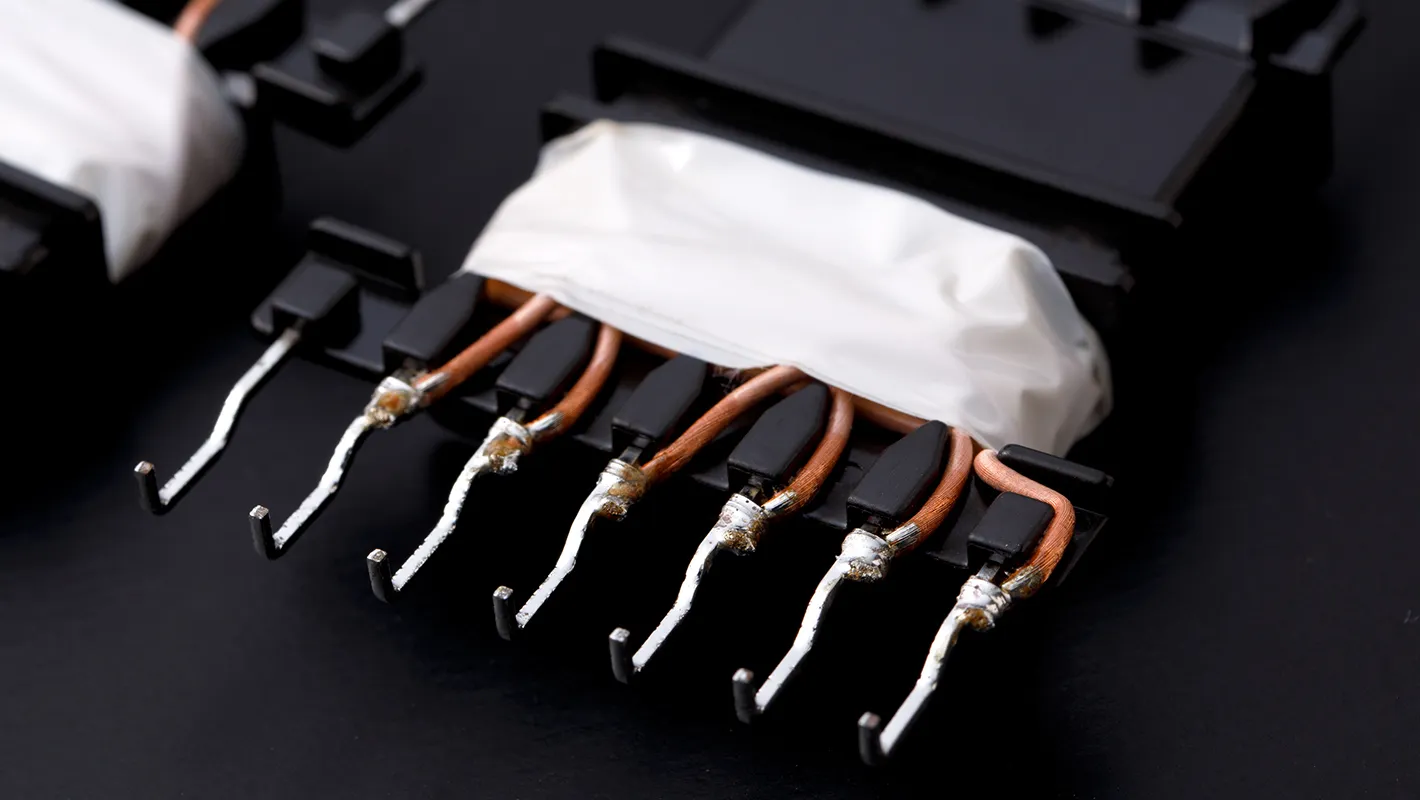

02Soldering

SoundSoldering utilizes the power of sound to create interatomic bonds between solder and parts. This allows to tin parts without the need for flux.

-

03

03Rotation

SoundRotation utilizes the power of sound and rotational motion to create continuous bonded seams with interatomic bonds between layers. Our SoundRotation systems, equipped with the world’s largest rotating resonators, can create continuous hermetic seals, all digitally controlled.

-

04

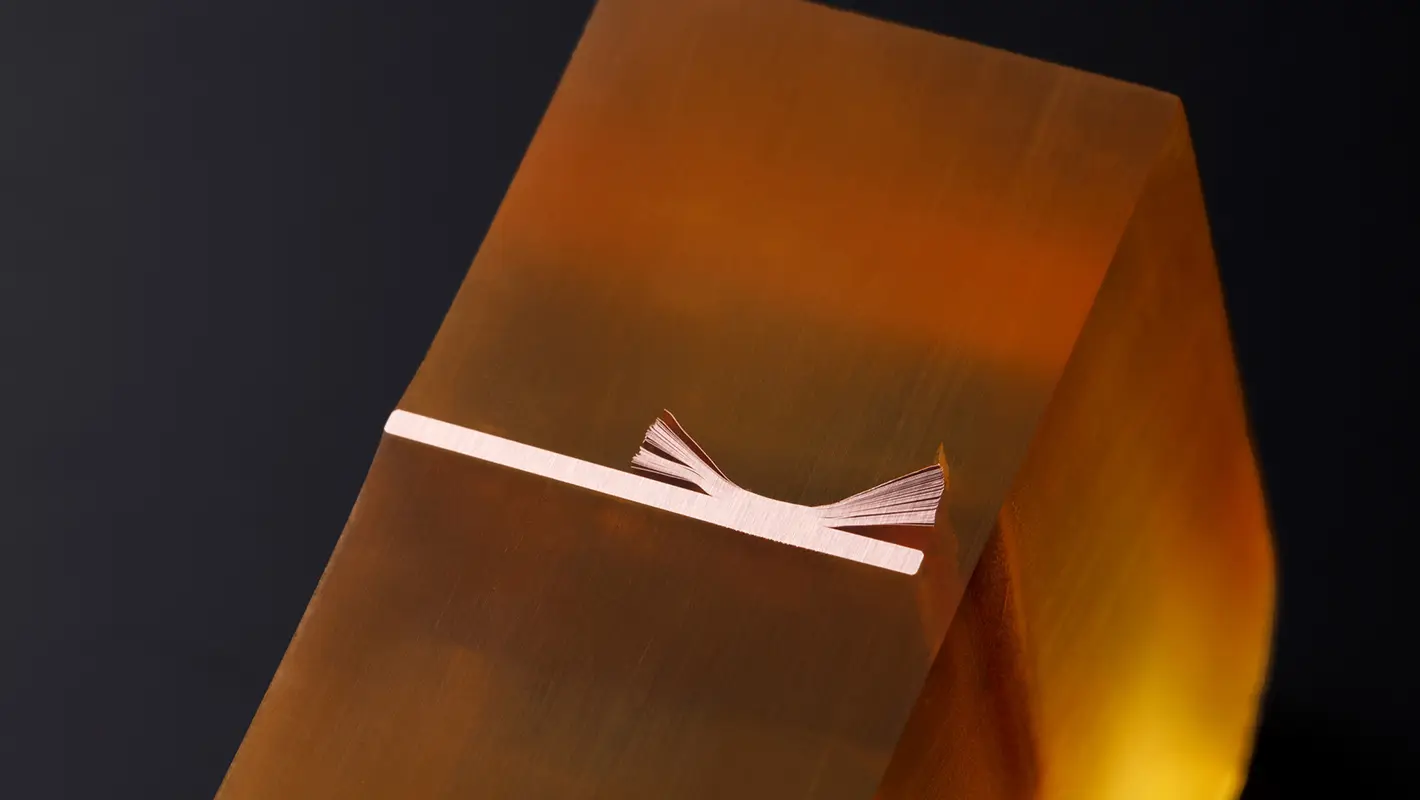

04Cutting

SoundCutting utilizes the power of sound for damage-free cuts in either atmosphere or liquid. This versatile cutting technology covers a wide range of metals, plastics, and even difficult-to-cut materials like SiC.